Hypertherm XPR300 Power Supply 208V, 078621

Hypertherm XPR300 Power Supply 208V, 078621

- Please Request availability & Freight quote

- Secure payments

XPR300 plasma cutting system

The XPR300® represents the most significant advance in mechanized plasma cutting technology, ever. This next generation system redefines what plasma can do by expanding its capabilities and opportunities in ways never before possible. With unmatched X-Definition® cut quality on mild steel, stainless steel and aluminum, the XPR300 increases cut speed, dramatically improves productivity and slashes operating costs. New ease-of-use features and engineered system optimization make the XPR300 easier to run with minimal operator intervention, while also ensuring optimal performance and unmatched reliability.

Industry-leading X-Definition cut quality

The XPR advances HyDefinition® cut quality by blending new technology with refined processes for next generation, X-Definition™ cutting on mild steel, stainless steel and aluminum.

- Consistent ISO range 2 results on thin mild steel

- Extended ISO range 3 cut quality results compared with earlier plasma technology

- Superior stainless steel cut quality across all thickness ranges

- Superior results on aluminum using Vented Water Injection™ (VWI)

-

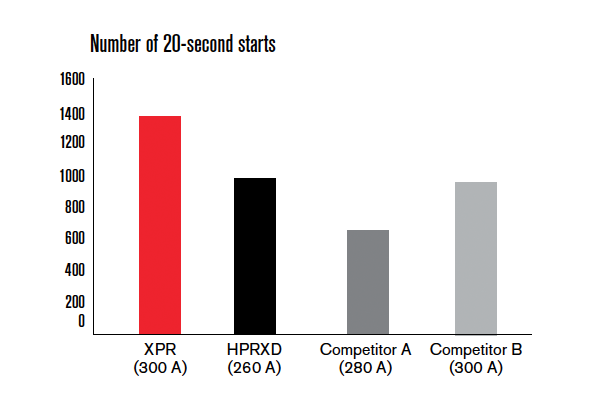

Optimized productivity and reduced operating costs

- Significantly reduced operating costs than previous generation technology

- Increased cut speeds on thicker materials

- Dramatic improvement in consumable life on mild steel applications

- Thicker piercing capability than competitive plasma systems

Engineered system optimization

XPR is engineered to deliver the highest quality cuts and optimal system performance automatically. Advanced power supply technology delivers highly responsive, rapid system feedback, and automatically intervenes to eliminate events that negatively impact system efficiency and consumable life.

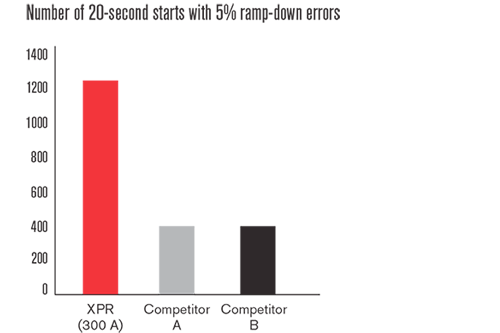

XPR’s Arc response technologyTM provides automatic torch and ramp-down error protection. Sensors in the power supply deliver refined diagnostic codes and significantly enhanced system monitoring information that reduces troubleshooting time and provides proactive system maintenance data for improved system optimization.

- Increases consumable life 3 times that of competitor’s systems by eliminating the impact of ramp down errors

- Reduces the impact of catastrophic electrode blowouts which can damage the torch at high current levels

Ease of use

- Intuitive operation and automatic monitoring redefine ease of use

- Full control of all functions and settings via the CNC

- Automatic system monitoring and specific troubleshooting codes for improved maintenance and service prompts

- EasyConnect™ torch lead and one hand torch-to-receptacle connection for fast and easy change-outs

- QuickLock™ electrode for easy consumable replacement

- WiFi in power supply can connect to mobile devices and LAN for multiple system monitoring and service

Advanced process control and delivery

Four console options – Core™, CorePlus™, Vented Water Injection™ (VWI™) and OptiMix™ – offer unmatched mild steel cut quality with each console delivering successively enhanced cutting capabilities on stainless steel and aluminum. All consoles can be fully controlled through the CNC for high productivity and ease of use.

Gas-connect console gases/fluids

Core CorePlus Vented Water Injection (VWI) OptiMix O2/N2/Air X X X X Ar X X X F5/Ar/H2O X X H2-N2-Ar mixing X

Better for the environment, too!

The XPR300 system reduces consumable use, energy and the carbon footprint.

- 64% less consumable copper material is used per foot of cut

- System is 99.5% recyclable and packaging is 100% recyclable

- The carbon impact of magnetics is 77% lower than its predecessor

- 62% higher power-to-weight ratio and 14% faster cuts

-

Maximum open-circuit voltage (U0) 360 VDC Maximum output current 300 A Maximum output power 66.5 kW Output voltage 50 VDC–210 VDC 100% duty arc voltage 210 V Duty cycle rating 100% at 66.5 kW, 40° C (104° F) Operational ambient temperature range -10° C–40° C (14° F–104° F) Power factor 0.98 at 66.5 kW Cooling Forced air (Class F) Insulation Class H EMC emissions classification (CE models only) Class A Lift points Top lift eye weight rating 680 kg (1,500 lb.)

-

Cut chart thickness mm inches Pierce capacity Mild steel (argon-assist) 50 2 Mild steel (standard O2) 45 1–3/4 Stainless steel 38 1–1/2 Aluminum 38 1–1/2 Severance capacity Mild steel 80 3–1/8 Stainless steel 75 3 Aluminum 50 2 This does not represent a complete list of processes or thicknesses that are available.

Console Cutting gases Current (A) Cut chart thickness (mm) Approximate cutting speed (mm/min) Cut chart thickness (in.) Approximate cutting speed (ipm) Mild steel Core™, CorePlus™, VWI™, and OptiMix™ O2 plasma 30 0.5 5348 0.018" 215 O2 shield 3 1153 0.135" 40 5 726 3/16" 30 O2 plasma 50 3 3820 0.105" 155 Air shield 5 2322 3/16" 95 8 1369 5/16" 55 O2 plasma 80 3 5582 0.105" 225 Air shield 6 3048 1/4" 110 12 1405 1/2" 55 O2 plasma 130 3 6502 0.135" 240 Air shield 10 2680 3/8" 110 38 256 1-1/2" 10 O2 plasma 170 6 5080 1/4" 200 Air shield 12 3061 1/2" 115 25 1175 1" 45 50 267 2" 10 O2 plasma 300 12 3940 1/2" 155 Air shield 25 1950 1" 75 50 560 2" 21 80 165 3" 7 Stainless steel Core, CorePlus, VWI, and OptiMix N2 plasma 40 0.8 6100 0.036" 240 N2 shield 3 2683 0.105" 120 6 918 1/4" 32 VWI and OptiMix F5 plasma 80 3 4248 0.135 140 N2 shield 6 1916 1/4" 70 12 864 1/2" 34 OptiMix H2-Ar-N2 plasma 170 10 1975 3/8" 80 N2 shield 12 1735 1/2" 65 38 256 1-1/2" 10 H2-Ar-N2 plasma 300 12 2038 1/2" 80 N2 shield 25 1040 1" 40 50 387 2" 17 75 162 3" 6 VWI and OptiMix N2 plasma 300 12 2159 1/2" 85 H2O shield 25 1302 1" 50 50 403 2" 15 Aluminum Core, CorePlus, VWI, and OptiMix Air plasma 40 1.5 4799 0.036 240 Air shield 3 2596 1/8" 85 6 911 1/4" 32 VWI and OptiMix N2 plasma 80 3 3820 1/8" 140 H2O shield 6 2203 1/4" 80 10 956 1/2" 28 N2 plasma 130 6 2413 1/4" 95 H2O shield 10 1702 3/8" 70 N2 300 20 870 3/4" 35 12 2286 1/2" 90 H2O shield 25 1302 1" 50 50 524 2" 20 OptiMix H2-Ar-N2 plasma 300 12 3810 1/2" 150 N2 shield 25 2056 1" 80 50 391 2" 15